Today, the foundry complies with “3 x E” rule

Economy

Ergonomics

Energy-saving

- Guaranteed high quality of products.

- Experienced and qualified personnel.

- Wide product range.

- Modern, environmentally friendly technologies.

Modernized machinery, incl.:

Precision Foundry

Production Technology: LOST WAX METHOD – characterized by high precision of surface mapping which significantly reduces the cost of machining, and thus, energy consumption. Castings made in our Foundry are the most cost-beneficial precision castings on the market.

LAEMPE Core-making Machines

New Investments

Danish DISAMATCH 24/28 / Moulding Line

Advantages of the new line:

- high precision and stable dimensions

- satisfactory moulding speed in relation to the size of moulds

- high quality of castings surface

STEM suspension shot-blasting machine

Advantages of the new line:

- components to be blasted: ductile and grey cast iron castings

- castings dimensions: 250×250×250mm

- weight of the blasted castings: 18kg

- capacity: 600 tones/month, work on 3 shifts/day

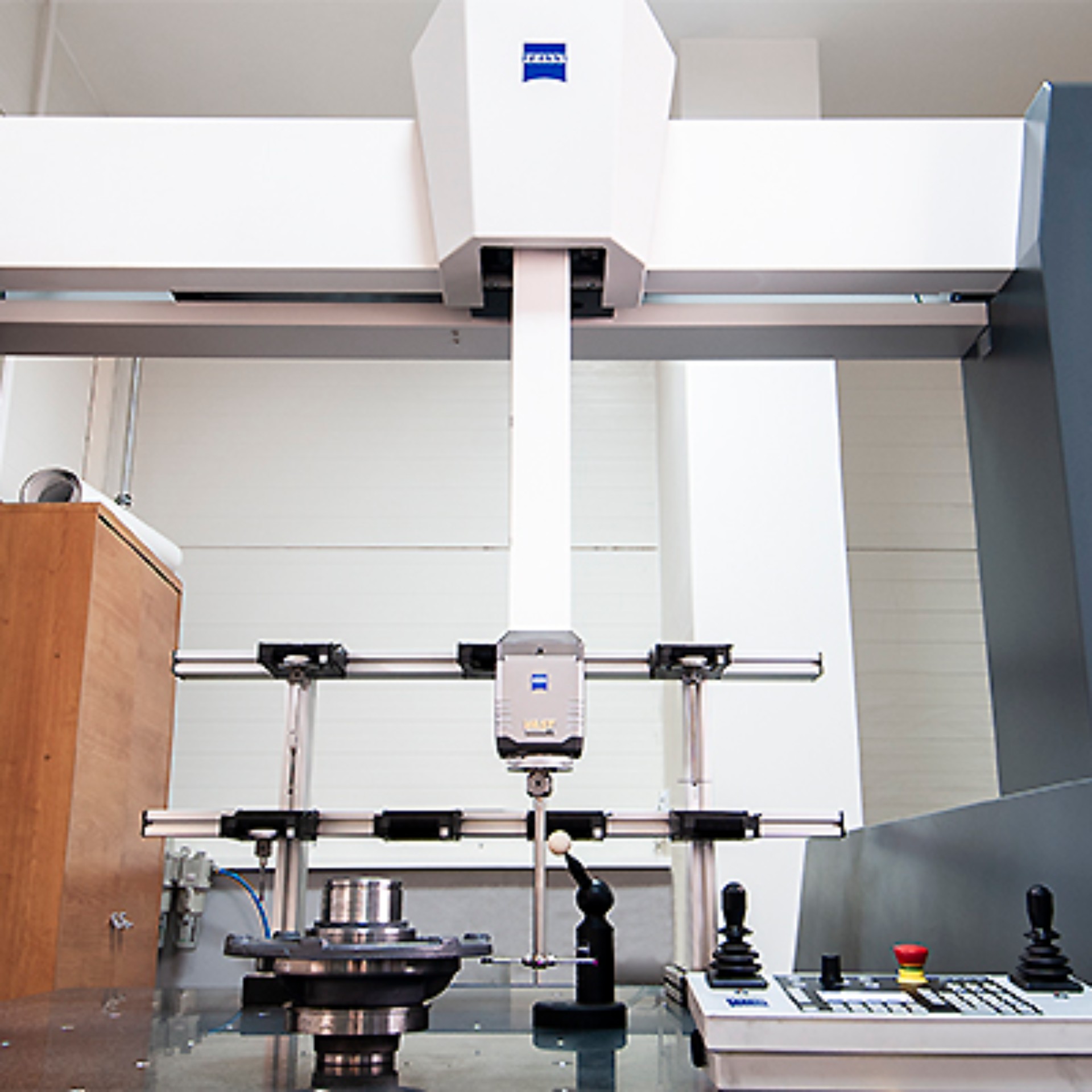

DMG Mori CNC Machine Tools

Two CNC Turning Lathes

Name: DMG MORI NLX 2500/700

Manufacture year: 2015

Turning diameter: 366mm

Turning length: 700mm

Head: 12 driven positions

Electro spindle: 15 kW const.

Two CNC horizontal centers

Name: DMG MORI NHX4000

Manufacture year: 2015

Tray: 400x400mm

Spindle: 15,000 rpm, power: 18.5 kW const.

Max weight of a detail: 400kg